Power Quality Measurement

KTR Electrical Solutions has a dedicated mission which is to protect our clients’ sensitive electrical / electronic equipment and data from damage. We offer PQ measurement and data collection services to ensure you document your power factor, harmonic issues, or motor starting issues. This will also assist with documenting the performance of a harmonic filter or VFD drive system.

Measurement Services to verify compliance with the following standards and regulation

- Harmonic Distortion – IEEE 519 Compliance

- Voltage Flicker – IEEE Standard 1453

- Motor Start & Voltage Sag Measurement – IEEE 1564

- Power Factor

- IEEE Standard 1159 – Recommended Practice for Monitoring Electrical Power Quality

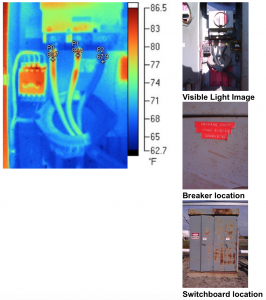

Thermography

Electrical Infrared Inspections

KTR Electrical Solutions use thermal images to detect defective components, potential overloads, and elevated temperatures within your power distribution system, allowing replacement of circuit components before failure. This proven process eliminates costly downtime or further damage to the electrical system. Hot spots are typically caused by unbalanced or overloaded circuits, loose connections, or defective equipment. These conditions are often overlooked during routine evaluations of facilities and can result in the release of heat that will be visible only through infrared thermography detection services.

We perform infrared scan on all high voltage and low voltage electrical equipment:

- switchgear

- outdoor breakers

- transformers

- starters

- motors

- MCCs

- Bus bar systems

Schedule your test today at 610 670 6061.

Benefits of an Infrared Scan

In addition to the direct financial savings, valuable time is saved by incorporating an annual infrared electrical survey into your PM program. Providing accurate information regarding the integrity of your electrical system’s components cuts down on maintenance time, prevents costly replacements and can eliminate unforeseen outages and downtime. An infrared (thermal) electrical inspection survey can help:

- Maintain the integrity of your facility’s electrical system

- Reduce electrical fire hazards

- Provide uninterrupted power to tenants/clients/employees

- Detect faulty connections/overloaded circuits

- Provide a snap shot in time of the condition of your mechanical systems, motors, bearings, etc.

- Preventative or predictive maintenance programs save money by reducing:

- pre-mature equipment failure

- emergency overtime

- overnight shipment of parts

- insurance premiums (many insurance companies give discounts for performing regular infrared inspections)

- loss of revenue due to downtime